Six Sigma, a data-centric framework for process improvement originating from Motorola in the 1980s and now an international standard for excellence, has been embraced by Pittsburg, California, as a cornerstone of its manufacturing supremacy. The region's businesses are leveraging lean Six Sigma principles to enhance operational efficiency and product quality through targeted Six Sigma training, which equips workers with tools for waste elimination and process optimization. Achieving Six Sigma Black Belt status is a significant career milestone in Pittsburg, reflecting not just technical expertise but also leadership abilities. This certification underscores an individual's mastery of Six Sigma techniques, focusing on continuous improvement, statistical control, and quality management. The integration of Lean Six Sigma principles has revolutionized process improvement across industries by providing practical tools to systematically reduce defects and variability. In Pittsburg, Six Sigma Black Belts play a crucial role in guiding projects towards breakthrough results, driving operational excellence, and delivering tangible business outcomes, making the Six Sigma Black Belt certification highly esteemed within the local business community. Six Sigma methodology relies on the DMAIC framework—Define, Measure, Analyze, Improve, Control—and is supported by advanced training programs aimed at fostering a culture of continuous improvement and innovation.

In the bustling manufacturing hub of Pittsburg, California, the integration of Statistical Process Control (SPC) has become a cornerstone for achieving operational excellence. This article delves into the transformative role of Six Sigma within Pittsburg’s industrial landscape, highlighting how it synergizes with Lean Six Sigma principles to optimize processes and enhance quality control. We will explore the path to Six Sigma certification, demystify the methodologies and concepts that underpin Six Sigma, and examine the journey towards earning the coveted title of a Six Sigma Black Belt. Additionally, we’ll discuss the impact of comprehensive Six Sigma training programs on Pittsburg’s organizations, offering insights into elevating performance standards in the industry. Join us as we navigate through these critical aspects of Six Sigma and its pivotal role in propelling Pittsburg CA towards a future of unparalleled manufacturing precision and efficiency.

- Understanding Six Sigma and Its Role in Pittsburg CA Manufacturing Excellence

- Leveraging Lean Six Sigma Principles for Process Improvement in Pittsburg CA

- The Path to Six Sigma Certification: A Guide for Pittsburg CA Professionals

- Decoding What Is Six Sigma: Methodologies and Concepts Explained

- The Journey to Becoming a Six Sigma Black Belt in the Pittsburg CA Business Landscape

- Effective Six Sigma Training Programs for Pittsburg CA Organizations and Their Impact on Quality Control

Understanding Six Sigma and Its Role in Pittsburg CA Manufacturing Excellence

Six Sigma is a disciplined, data-driven approach and methodology for eliminating defects in manufacturing processes through a set of quality management methods. Originally developed by Motorola in the 1980s, it has since become a global standard for process improvement and product excellence. In Pittsburg, California, Six Sigma serves as a cornerstone for achieving manufacturing excellence. Leveraging lean Six Sigma principles, local businesses can significantly enhance their operational efficiency and product quality. These principles are integrated into six sigma training programs, which empower workers with the tools and techniques necessary to identify and eliminate waste, reduce variability, and optimize production processes.

Six Sigma certification is a testament to an individual’s proficiency in these methodologies and their commitment to maintaining high standards of quality control. In Pittsburg, the pursuit of six sigma black belt certification is a clear path for professionals looking to advance their careers by mastering the six sigma methodology. This advanced level of certification not only signifies expertise but also embodies leadership skills required to lead continuous improvement projects and drive business process improvements. By implementing lean Six Sigma principles, Pittsburg’s manufacturing sector is poised to achieve sustainability, consistency, and a competitive edge in today’s dynamic marketplace.

Leveraging Lean Six Sigma Principles for Process Improvement in Pittsburg CA

In Pittsburg, California, the integration of Lean Six Sigma principles has become a cornerstone for process improvement across various industries. These methodologies are not just theoretical frameworks but practical tools that help organizations in Pittsburg to systematically eliminate defects and variability in processes through a rigorous, data-driven approach. The Six Sigma certification program equips professionals with the necessary skills to implement these techniques effectively. By understanding what Six Sigma is at its core, individuals can delve into the Six Sigma methodology, which emphasizes continuous improvement and adherence to statistical control. This certification is a testament to an individual’s proficiency in applying Six Sigma principles and tools within their organization. For instance, Six Sigma Black Belts are critical assets in this endeavor, leading projects that aim to reduce process variability and increase customer satisfaction by enhancing product quality and service efficiency. The Lean Six Sigma training available in Pittsburg provides the necessary framework for these professionals, enabling them to identify waste, streamline operations, and achieve sustainable improvements in production processes. By applying Lean Six Sigma principles, businesses in Pittsburg can transform their operations, reduce costs, and improve performance outcomes, ultimately positioning themselves competitively in the marketplace.

The Path to Six Sigma Certification: A Guide for Pittsburg CA Professionals

Embarking on the path to Six Sigma certification is a transformative journey for professionals in Pittsburg, CA, seeking to master the principles of process improvement and operational excellence. Six Sigma, a methodology that enables organizations to optimize their processes through rigorous statistical control, has become a standard for quality across various industries. To achieve Six Sigma certification, one must delve into the lean Six Sigma principles, which emphasize the elimination of waste and the efficient use of resources to enhance productivity. The certification process typically begins with foundational training that introduces the concepts of what is Six Sigma, its significance in quality management, and the application of statistical tools to control processes.

As professionals advance through the Six Sigma training program, they encounter more sophisticated aspects of the Six Sigma methodology, culminating in the attainment of a Six Sigma Black Belt. This prestigious certification signifies an individual’s mastery over the techniques and tools required to lead complex projects aimed at process improvement. The training encompasses comprehensive modules that cover DMAIC (Define, Measure, Analyze, Improve, Control), DMADV (Define, Measure, Analyze, Design, Verify), and other advanced statistical methodologies integral to Six Sigma problem-solving. Aspiring professionals in Pittsburg are encouraged to commit to a structured learning path that includes mentorship, hands-on projects, and stringent examinations, ensuring they are well-versed in the applications of lean Six Sigma principles and prepared to contribute significantly to their organizations’ success.

Decoding What Is Six Sigma: Methodologies and Concepts Explained

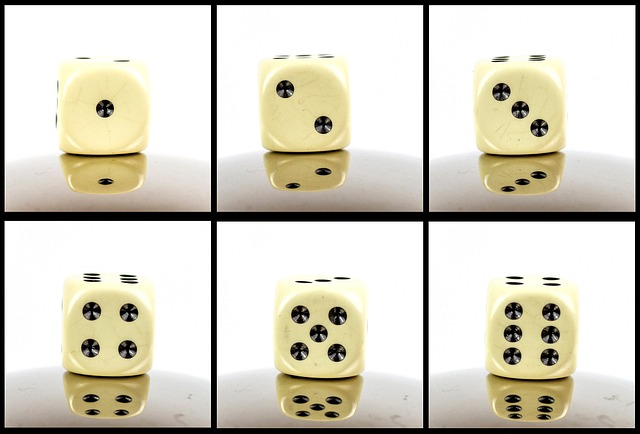

Six Sigma is a disciplined, data-driven approach and methodology for eliminating defects in any process – from manufacturing to transactional and from product to service. Originally developed by Motorola in 1980s, it has since become a globally recognized standard for excellence. The core objective of Six Sigma is to improve the quality of process outputs by identifying and removing the causes of defects and minimizing variability in manufacturing and business processes. Lean Six Sigma integrates the lean principles with Six Sigma methodologies, focusing on the reduction of waste and optimizing resource use while pursuing the six sigma aim of reducing process variation to six standard deviations from the mean, hence the term ‘Six Sigma’.

To achieve this, Six Sigma employs a set of powerful tools and techniques through a structured problem-solving method. It is implemented in DMAIC (Define, Measure, Analyze, Improve, Control) phases to systematically address process improvement and optimization. A key role in the deployment of Six Sigma is the Six Sigma Black Belt – an individual trained at a black belt level with extensive knowledge of statistical methods and tools, responsible for leading projects to achieve breakthrough improvements. This rigorous Six Sigma training not only enhances problem-solving skills but also instills a culture of continuous improvement within organizations. The principles of Lean Six Sigma are designed to create more value for customers with fewer resources, thereby driving efficiency and effectiveness in processes across various industries. Whether through Six Sigma certification programs or the cultivation of Six Sigma Black Belts, the influence of Six Sigma methodology is profound, shaping a quality-centric approach that has proven effective across the globe.

The Journey to Becoming a Six Sigma Black Belt in the Pittsburg CA Business Landscape

In the bustling business landscape of Pittsburg, California, professionals are increasingly recognizing the transformative power of Six Sigma methodologies in enhancing operational excellence. The journey to becoming a Six Sigma Black Belt in this region is a testament to the commitment to quality and process improvement that defines the area’s business ethos. Aspiring black belts embark on an intensive training program, delving into the lean Six Sigma principles that form the backbone of this renowned certification. This rigorous training encompasses both the theoretical underpinnings and practical applications of Six Sigma, equipping individuals with the tools necessary to navigate complex business processes and drive continuous improvement. The curriculum is designed to cover all aspects of the Six Sigma methodology, from DMAIC (Define, Measure, Analyze, Improve, Control) to the intricacies of statistical process control, ensuring that candidates are well-versed in both the philosophy and the statistical techniques required for successful implementation.

The Six Sigma black belt certification is a prestigious achievement that signifies mastery over the Six Sigma body of knowledge and its application within an organizational context. In Pittsburg, where businesses operate at the cutting edge of innovation, this certification holds significant weight, opening doors to leadership roles in process optimization, project management, and quality assurance. The journey to attaining this certification is not for the faint-hearted; it demands a deep dive into Six Sigma’s multifaceted approach to problem-solving, which includes project management skills, critical thinking, and data analysis capabilities. As a result, individuals who complete this certification are highly valued for their ability to drive process efficiency and deliver measurable business results, making the Six Sigma black belt a prized asset in the Pittsburg CA business landscape.

Effective Six Sigma Training Programs for Pittsburg CA Organizations and Their Impact on Quality Control

In the realm of quality control and process improvement, Six Sigma stands as a highly effective methodology for organizations in Pittsburg, CA. Six Sigma training programs tailored to local businesses are instrumental in empowering teams with the necessary skills to refine their operations and enhance product quality. These training sessions, which often lead to Six Sigma certification, are designed to impart both the theoretical underpinnings of the methodology and practical applications of its principles. By participating in a Six Sigma certification program, Pittsburg’s organizations can cultivate experts well-versed in Lean Six Sigma principles, which emphasize not just efficiency but also a systematic approach to problem-solving. The impact of such training is profound; it equips professionals with the tools to identify and eliminate defects in processes, leading to significant improvements in quality control. This, in turn, fosters a culture of continuous improvement and data-driven decision-making within the organization, aligning with Six Sigma’s overarching goals.

Furthermore, the Six Sigma methodology encompasses a variety of strategies that are directly applicable to various industries within Pittsburg’s diverse economic landscape. The Lean Six Sigma approach, in particular, is revered for its ability to streamline processes by eliminating waste and reducing variation, thereby enhancing overall efficiency. A Six Sigma Black Belt, the highest level of certification, signifies an individual’s proficiency in leading such transformative projects. By implementing these methodologies, organizations can achieve a higher degree of consistency and reliability in their operations, ultimately delivering products and services that meet or exceed customer expectations. The ripple effect of Six Sigma training is far-reaching, influencing not just the quality of output but also fostering a competitive edge for businesses looking to thrive in today’s fast-paced market.

In conclusion, the application of Six Sigma in Pittsburg CA has proven to be a transformative force within its manufacturing sector, fostering excellence through meticulous process control and continuous improvement. By integrating Lean Six Sigma principles, local businesses have not only enhanced their productivity but also elevated their quality standards, setting a benchmark for operational efficiency. Aspiring professionals in the region have clear pathways to six sigma certifications, which equip them with the expertise required to become pivotal agents of change within their organizations. A deep understanding of Six Sigma methodologies, underpinned by comprehensive training programs, has empowered Pittsburg CA’s workforce to effectively manage and optimize processes. As such, the adoption of Six Sigma is not just a statistical tool but a strategic imperative for businesses aiming to thrive in today’s competitive landscape.